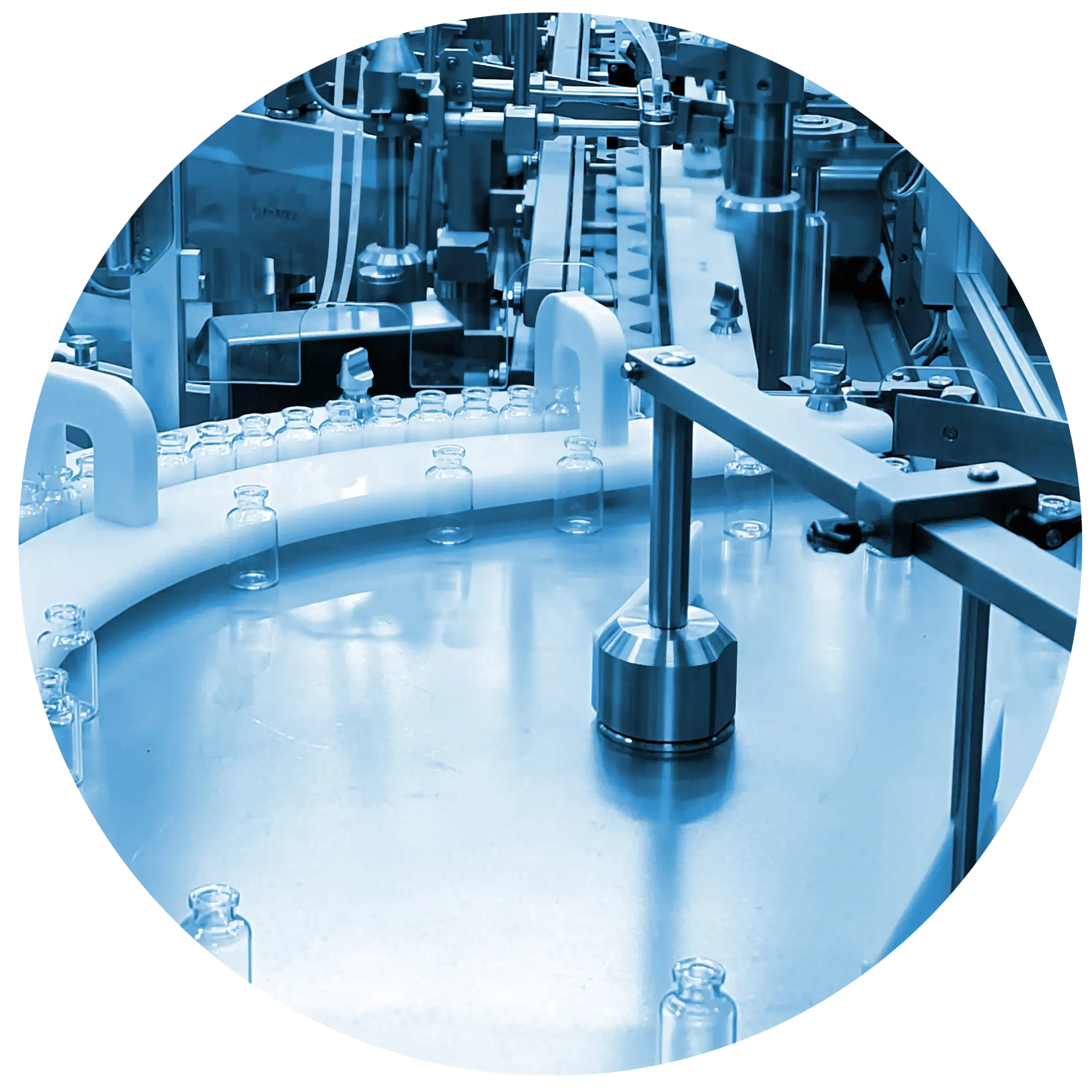

IDT excels in aseptic fill & finish services

As a trusted leader in the pharmaceutical industry, IDT excels in aseptic fill & finish services. With a focus on quality and safety, we offer bespoke manufacturing of sterile products, providing comprehensive fill and finish solutions for liquid and lyophilised forms.

Backed by a sterile suite designed for manufacturing investigational medicines, our nimble tech transfer and production processes offer flexible solutions to our clients. This enables the efficient and reliable manufacturing of sterile medicines in a full cGMP environment.

Key Benefits:

- Customised Manufacturing: Tailored solutions for sterile product production to meet specific client requirements.

- Liquid and Lyophilised Forms: Expertise in fill and finish for a wide range of product formulations.

- Stringent Quality Control: Rigorous measures ensure the integrity, purity, and efficacy of the final sterile products.

- Regulatory Compliance: Adherence to global standards and guidelines for sterile product manufacturing.

With our industry knowledge, advanced facilities, and commitment to excellence, IDT is your trusted partner for aseptic fill & finish services. Through our strong collaboration with MMIC, we offer the assurance of working with a reputable CDMO that prioritises quality, precision, and efficiency in sterile product manufacturing. Experience the benefits of our expertise and the confidence that comes from partnering with a leader in the industry.

IDT is a trusted pharmaceutical CDMO specialising in aseptic fill & finish services. With a focus on manufacturing sterile products in both liquid and lyophilised forms, we offer comprehensive solutions tailored to meet our clients' needs. Our capabilities and expertise in aseptic fill and finishing are unparalleled, ensuring the highest quality standards throughout the manufacturing process.

Here are the key Key advantages of choosing IDT for aseptic fill & finish:

- Sterile Suite: Our state-of-the-art sterile suite is specifically designed to accommodate the manufacturing of investigational medicines, providing a controlled environment for aseptic processes.

- Single Quality System: Our on-site support covers manufacturing, chemistry, microbiological testing, stability studies, and finished product release. Under one quality system, we ensure streamlined coordination and regulatory compliance.

- Seamless Product Transitions: At IDT, we ensure seamless product transitions from manufacture to analysis and release. Our integrated approach, handled by the same expert team, eliminates delays and complexities of multiple tech transfers.

You can trust IDT's expertise and capabilities in aseptic fill & finish to deliver exceptional sterile product solutions, meeting the highest quality standards and regulatory compliance.

IDT is a pharmaceutical manufacturer operating in a regulated cGMP environment. Our facility has undergone comprehensive audits and is accredited by key regulatory authorities, including the Australian Therapeutic Goods Administration, the U.S. Food and Drug Administration, and the Japanese Ministry for Health Labour and Welfare.

Our adherence to high-quality GMP standards extends to Europe and Canada through The Mutual Recognition Agreement. These certifications affirm our commitment to upholding stringent quality control measures and complying with international regulatory requirements for aseptic fill and finish processes.

Full-Spectrum API Manufacturer (CDMO)

At IDT, we excel in providing comprehensive support for aseptic fill and finish processes, specialising in both liquid and lyophilised forms. Our expertise in this area enables us to meet the increasing demand for sterile products with precision and efficiency. Key highlights of our capabilities include:

- Aseptic Fill and Finish Expertise: We have developed a strong proficiency in the aseptic handling and filling of liquid and lyophilised products, ensuring their sterility and integrity.

- Robust Quality Control: Our stringent quality control measures, including in-house chemistry and microbiological finished product release testing, guarantee the highest quality standards.

- Streamlined Processes: With in-house product transitions handled by the same team of experts, we eliminate the challenges associated with multiple tech transfers.

- Regulatory Compliance: Our operations strictly adhere to cGMP standards, ensuring compliance with regulatory requirements and maintaining the highest level of product safety and efficacy.

IDT is a trusted partner for the development and manufacturing of sterile products in both liquid and lyophilised forms. Our expertise in aseptic fill and finish, along with our commitment to quality control, streamlined processes, and regulatory compliance, ensures reliable and high-quality outcomes for our clients.

Aseptic Fill & Finish

Aseptic filling and lyophilization is one of the most critical processes in the production of pharmaceutical and biopharmaceutical products. Our sterile production facilities have dedicated cleanrooms with segmented laminar flow areas across the rooms, separated by laminar flow hoods ranging from ISO 8 to ISO 4.8 (equivalent to Grade D down to Grade A classifications) depending on the stage of the process and the area the product interacts with. IDT’s sterile manufacturing suite contains the following equipment:

- Vial washer

- Filling and capping machines

- BOC Edwards freeze dryer

- Formulation suite

- Dry heat oven / Lyophilizer.

- Autoclave

- Various monitoring, testing and transporting devices

- 4000L, 400L and 100L processing plants which can be used for upstream extractions, reactions, distillations and purification steps in the manufacture of biopharmaceutical products.

Contact IDT Australia

If you’re looking for quality, turnkey cGMP contract manufacturing services, please get in touch with us today.